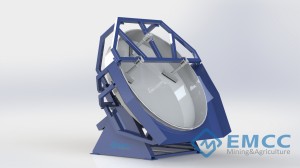

The disc granulator produces granules by continuously rotating the disc. The small series is driven by the motor to drive the reducer and then directly drives the disc to rotate, while the larger series is driven by the main motor to drive the pulley and belt, and the small gear is driven by the reducer. The small gear and the large gear fixed on the bottom of the disk mesh with each other, and work in opposite directions.The big gear is specially designed to be installed on the main shaft ,fixed on the frame adjustment plate to support the work of the entire pelletizing plate.

Equipment advantages:

Equipment advantages:

1. The angle of the granulating disc of the disc granulator adopts an integral arc structure, and the granulation rate can reach more than 93%.

2. The pelletizing tray is equipped with three discharge ports, which is convenient for intermittent production operations, greatly reduces labor intensity and improves labor efficiency. The reducer and motor are driven by flexible belts, which can start smoothly, reduce the impact of cushioning, and increase the service life of the equipment.

3. The bottom of the pelletizing disc is reinforced by multiple radiant steel plates, which is firm and durable without deformation. The thickened, heavier, and sturdy chassis design does not require anchor screws to fix it, and it runs smoothly. The main gear of the granulator adopts frequency quenching, and the service life is doubled.

This machine has the advantages of uniform granulation, granulation rate, stable operation, sturdy and durable equipment, and long service life. It is an ideal equipment for users to choose.

Contact

Have a Question or need a quote?

Whether you know exactly what you need,

or you’re not sure where to start, we can help.

Equipment Quick Links

Production line equipment

Batching Systems

Drum Dryer

Drum Cooler

Screening Equipment

Fertilizer Coating Machine

Packaging Machine

Supporting equipment

Crusher

Mixer

Elevator

Belt conveyor

Supporting environmentally friendly dust removal equipment

Pulse Dust Collector

Spray Tower

Boiler

Combustion Device