The crop nutrition industry is being challenged to produce fertilizers that deliver key nutrients from the right source, at the right rate, and at the right time and place, with an emphasis on optimizing fertilizer use efficiency, minimizing product losses, and ensuring worker safety. Fertilizer coating technologies can meet these crop nutrition and fertilizer requirements.

How Controlled-Release Coatings Function

While different types of coatings may function in varying ways, in general, coatings in this context typically center around delaying the solubility/rate of moisture absorption of the granule, as this (along with temperature) is a primary factor in nutrient release. Waxes, oils, natural and synthetic polymers, and more, are all used as coatings to create controlled-release products.

The fertilizer coating technologies include dust control coatings, anti-caking and moisture-resistant coatings, coatings that deliver agronomic improvements, micronutrient binders and coloring agents to meet market preferences, and sustainable coatings to protect our environment. The coated fertilizer, can help you realize:

- Significant dust reduction for easier fertilizer handling and improved worker safety

Substantially reduced caking of fertilizer

Improved flowability for ease of handling, storage, and transportation

Enhanced fertilizer quality, color, and appearance

Improved stability of micronutrient fertilizer blends

Easier compliance with Environmental, Health, and Safety (EHS) Standards

Better compatibility in end-use applications.

Choosing The Right Coating Equipment

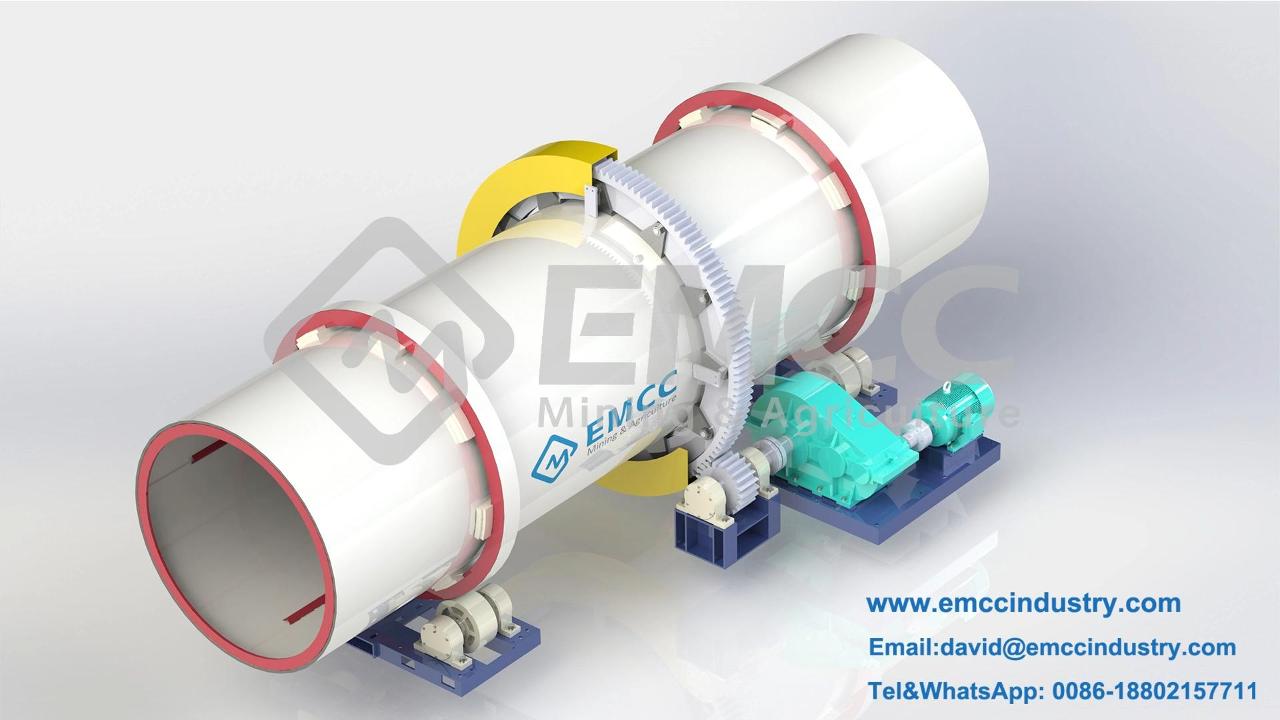

While several coating devices are available on the market, the industry standard for premium specialty fertilizer products is the coating drum.

Coating drums utilize rotary drum technology with an integrated spray system to apply and distribute coating onto fertilizer granules. As granules move through the drum, the coating solution is sprayed onto the material bed. The tumbling action that occurs as the drum rotates promotes an even distribution of the coating throughout the bed. Tumbler flights can be added to assist in bed agitation for maximum dispersion and uniformity.