Rotary Drum Dryer

China leading manufacturer of rotary drum dryer, EMCC design reliable machinery rotary dryer with high standards and quanlity in material for fertilizer plants with low price and cost.

Rotary DRUM DRYER

EMCC’s rotary dryer can be customized according to customers’ different requirements to achieve the best results.

We can design the length-to-diameter ratio of the cylinder, the lifting plate structural form and quantity, the flow direction relationship between hot air and material, the hot air inlet temperature, etc..

The fertilizer granules from the former granulator generally contain 6%-16% or even higher moisture, which needs to be dried to meet the moisture content standards, so as to meet the requirements of storage and fertilization. At present, the most commonly used drying equipment is the rotary dryer.

WORKING PRINCIPLE

The working principle of the rotary drum dryer is that under the action of dry air, the material rolls in the rotating drum to achieve the drying effect.

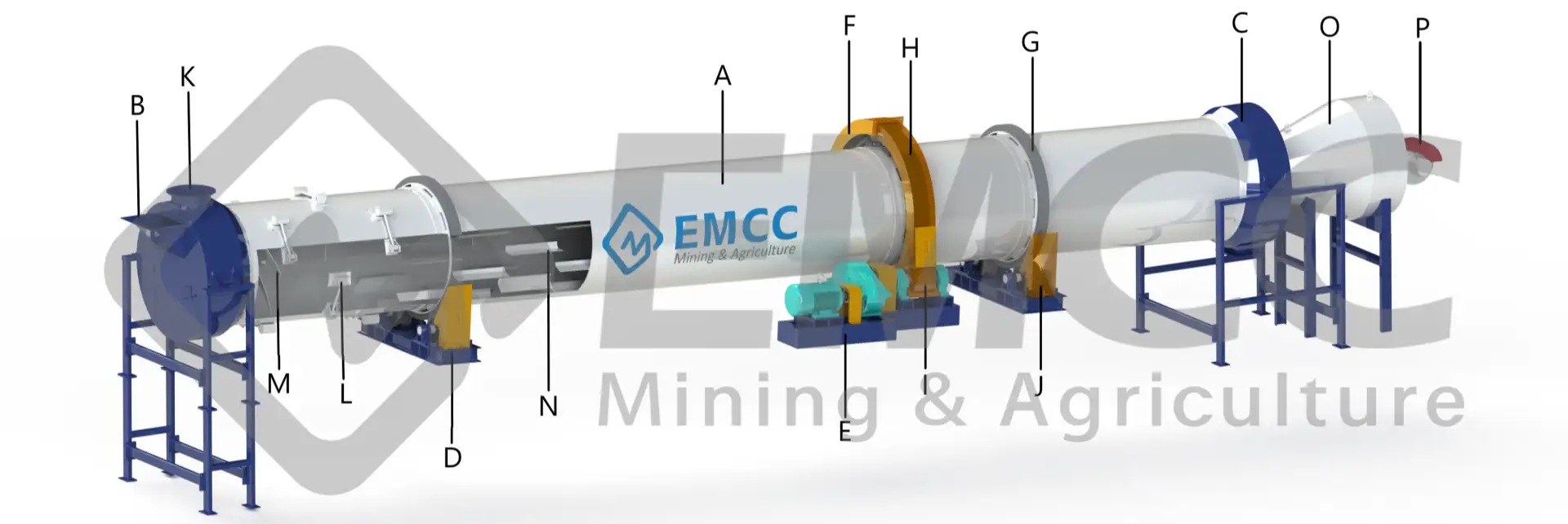

Rotary drum dryer is an inclined horizontal rotary cylinder, with a supporting device, a transmission device, a cylinder and a sealing structure such as inlet and outlet device.

The position of the drum is slightly tilted horizontally to allow gravity to help the material pass through the drum dryer. As the drum rotates, the lifting device picks up the material and drops it through the air stream to maximize heat transfer efficiency. When handling clumps, the rotation effect of the dryer can also further round and polish the granules.

FEATURES

Diameter: 0.8– 4.6m (2.625′ – 15.092′)

Capacity: 1 TPH – 200 TPH

The lifting device designed according to the specific situation can maximize the thermal conductivity between the material and the hot air flow.

A variety of materials are available, stainless steel optional for long service life.

Suitable heat sources can be recommended, such as fuel oil, heavy oil, natural gas, liquefied petroleum gas, coal or biomass, etc..

rotary DRYER COMPONENTS

APPLICATIONS & MATERIALS

The rotary drum dryer is the most important drying equipment in the industrial field. It can handle a wide range of raw materials and is suitable for almost any industry that requires an industrial drying solution, such as:

- Building aggregate

- Biosolids (municipal sewage waste and sludge)

- Fertilizer

- Fly ash

- Gypsum

- Inorganic chemical

- Limestone

- Manure

- Ore and concentrate

- Organic chemicals

- Paper sludge

- Plastic particle pellets and grains

- Potash fertilizer

- Regenerated dust

- Roof grain

- Rubber particle

- Salt and sugar

- Sand

- Steel mill slag

- Urea particles and crystals

photos

RESOURCES

Rotary Kilns vs. Rotary Dryers: What’s the Difference?

When it comes to thermal processing, confusion often arises in choosing

DIRECT VS. INDIRECT DRYING

Direct dryers are used more frequently than their indirect counterparts,