NPK Compound Fertilizer

China leading manufacturer of NPK compound fertilizer production line, EMCC design high-quality and low energy consumption granulator equipments for NPK mixed fertilizer plants with low price and cost.

NPK COMPOUND FERTILIZER

NPK compound fertilizer is a commonly mixed fertilizer that contains the three main nutrients required for plant growth: nitrogen (N), phosphorus (P), and potassium (K). These elements are crucial for the healthy growth of plants.

Nitrogen (N): Helps with the growth of plant leaves and is an important component of plant proteins and chlorophyll.

Phosphorus (P): Aids in the development of plant roots, the formation of flowers and fruits, and the process of energy conversion.

Potassium (K): Plays an important role in plant moisture regulation, disease defense, and photosynthesis, among other vital life processes.

The numbers in NPK mixed fertilizer typically represent the ratio of these three nutrients. For example, an NPK compound fertilizer labeled “10-20-10” means it contains 10% nitrogen, 20% phosphorus, and 10% potassium. This type of fertilizer is an effective way to provide a balanced supply of essential nutrients to plants and can be formulated to meet specific soil conditions and crop needs.

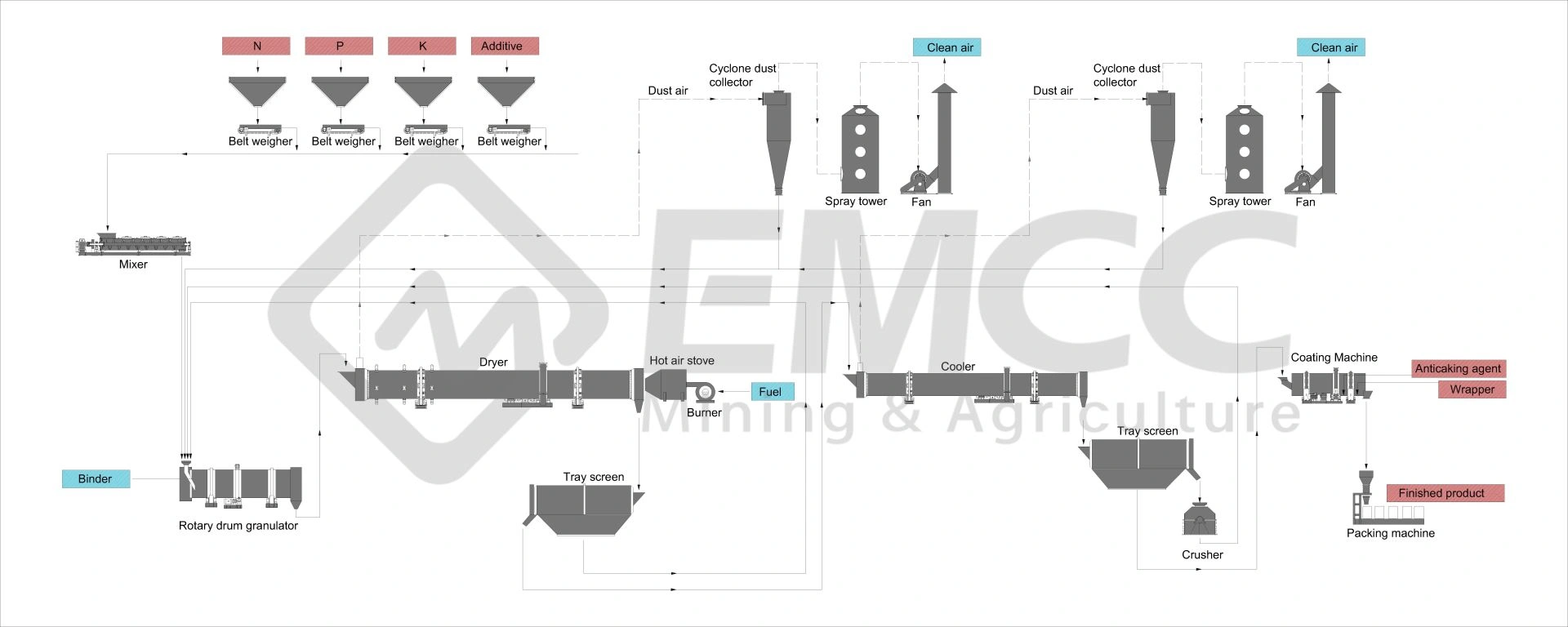

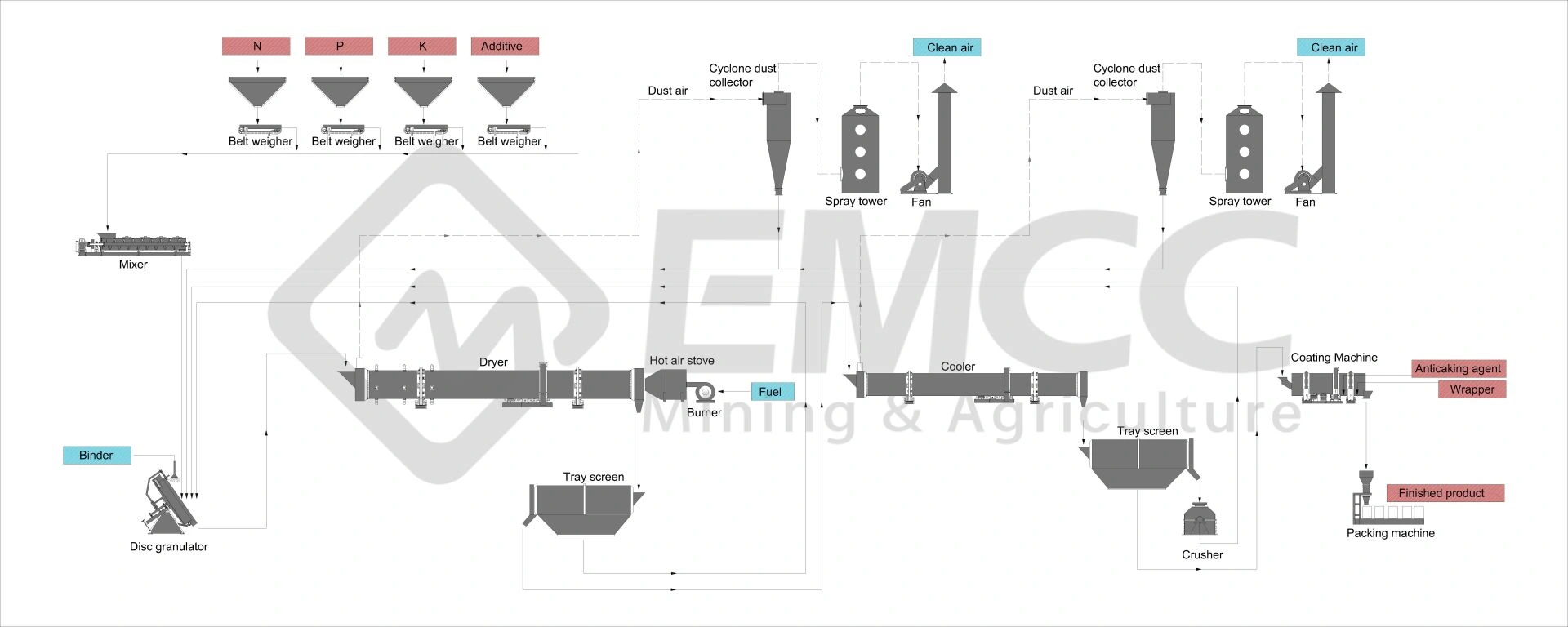

NPK COMPOUND FERTILIZER GRANULATION PROCESS

The granulation process of NPK compound fertilizer involves mixing nitrogen (N), phosphorus (P), potassium (K), and other nutrient elements and forming them into granules through physical or chemical methods. This process not only facilitates the transportation and use of the fertilizer but also helps in the uniform application and slow release of the fertilizer.

WET GRANULATION IS THE MOST COMMON GRANULATION PROCESS FOR NPK COMPOUND FERTILIZER:

Batching: First, different nitrogen, phosphorus, and potassium raw materials and other required materials are proportioned according to formula requirements at the batching station.

Mixing: The proportioned nitrogen, phosphorus, potassium fertilizers, possible fillers, and additives are mixed together to form a fertilizer mixture.

Granulation: The mixture is granulated in a granulator with the addition of water, through physical extrusion or agglomeration. Common granulation equipment includes rotary drum granulators and disc granulators.

Drying: The wet granules are dried in a dryer to remove excess moisture.

Cooling: The dried granules need to be cooled to lower the temperature and prevent particle agglomeration due to high temperatures.

Screening: After cooling, the granules are screened to separate the qualified granules from the unqualified powder or larger particles.

Coating: Qualified granular finished products add conditioning agents, etc. or change the colour.

Packaging: The qualified granules are packaged for sale or use.

China EMCC will consider factors such as the nature of the raw materials, the desired granule size, production scale, and economic benefits to design an appropriate granulation process.

RESOURCES

Fertilizer Numbers – What Is NPK

Looking at fertilizers in the store, you’ll usually find a

COMPLEX FERTILIZERS VS BLENDS

INTRODUCTION Shanghai Exceed Industry Co., Ltd. (hereinafter referred to as