Disc Granulator

As China leading manufacturer of fertilizer disc granulators/pan granulation machine, EMCC design high quality, efficiency, longevity and cost-effective disc pelletizers for compound or organic fertilizer plants with good price.

Disc Granulator

EMCC’s disc pelletizers is an important equipment for converting powdered materials into uniform round granules.

The disc granulator is composed of an inclined granulating disc, a driving device, a disc inclination adjusting mechanism, a frame, a charging sprayer, a scraper and other components.

WORKING PRINCIPLE

In the process of rotation, a small group of particles, formed by the liquid phase and the powder added to the disc from the front conveyor, roll towards the lower side of the disc and continuously adheres to the powder to increase the particle size due to the gravity and centrifugal force generated by the inclined disc in the process of rotation. At the same time, due to the friction between the material and the disc, the particles roll upward with the disc and overflow from the disc edge when they reach the finished granule size.

The main factors affecting the pan granulator are disc diameter, disc inclination, disc edge height, rotation speed, feeding position, scraper position and so on.

FEATURES

Diameter: 0.8– 4.5m (2.625′ – 14.764′ )

Capacity: 0.5 TPH – 15 TPH

Uniform finished granules and good automatic classification ability.

High granulation efficiency and low return ratio.

Visual and simple operation, easy to control, flexible formula.

The disc angle can be easily adjusted.

A variety of materials are available, stainless steel optional.

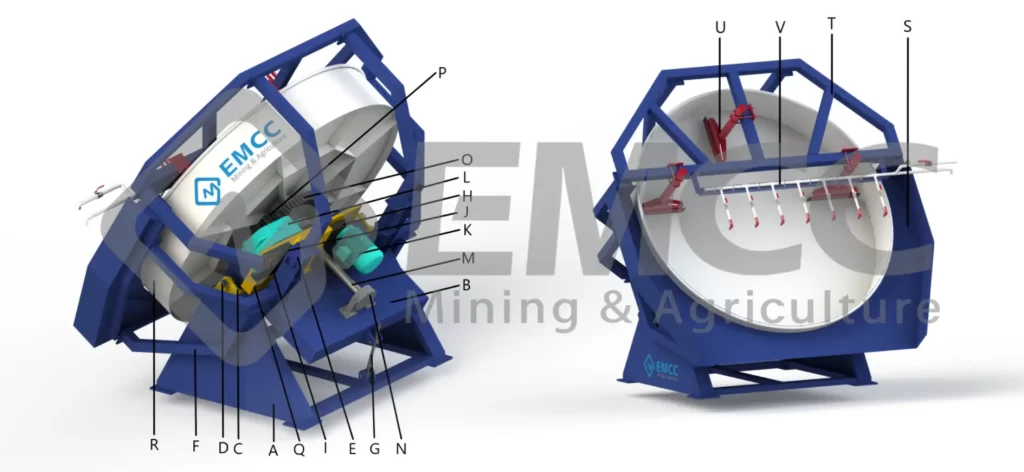

DISC GRANULATOR COMPONENTS

A – Install base

B – Installation platform

C – Platform support

D – Rotating shaft

E – Support column

F – Support arm

G – Adjustment device

H – Motor pulley

I – Reducer pulley

J – Drive belt

K – Motor

L – Reducer

M – Drive shaft

N – Bearing seat assembly

O – Big gear

P – Pinion

Q – Protective cover

R – Disc

S – Material receiving chute

T – Scraper holder

U – Scraper assembly

V – Spray assembly

APPLICATIONS & MATERIALS

China EMCC’s Disc Pelletizers can agglomerate everything from fine, dry feed materials, all the way to wet, sludge-like materials. Some of the most common applications for which pelletizer plants are built include:

Chemical Powders

Limestone / Gypsum

Fertilizers

Coal fines

Cement / Lime Kiln Dust

Flyash

Filter / Centrifuge Cake

Minerals and Ores

Vibrating Sludges

Pond tailings

EAF Dust

Photos

RESOURCES

Best Practices for Maintaining a Disc Granulator

The disc granulator, also known as a pan granulator, is a

THE USE METHOD AND PARAMETERS OF THE DISC GRANULATOR

The disc granulator can produce spherical pure organic fertilizer, organic-inorganic