Crusher

EMCC offers reliable machinery that meets high standards in design and material selection to ensure continuity in your production process

Crusher

In the fertilizer granulation, there are different particle size requirements for raw materials according to different production processes. Crusher is necessary to speed up the reaction and improve the raw material mixing uniformity, and more importantly, to make the raw materials more conducive to granulation after being crushed. During the production process, the unqualified large particles or lump materials formed also need to be returned to the granulation system after crushing.

Chain crusher is a commonly used fertilizer raw material crusher, which is divided into vertical chain crusher and horizontal chain crusher.

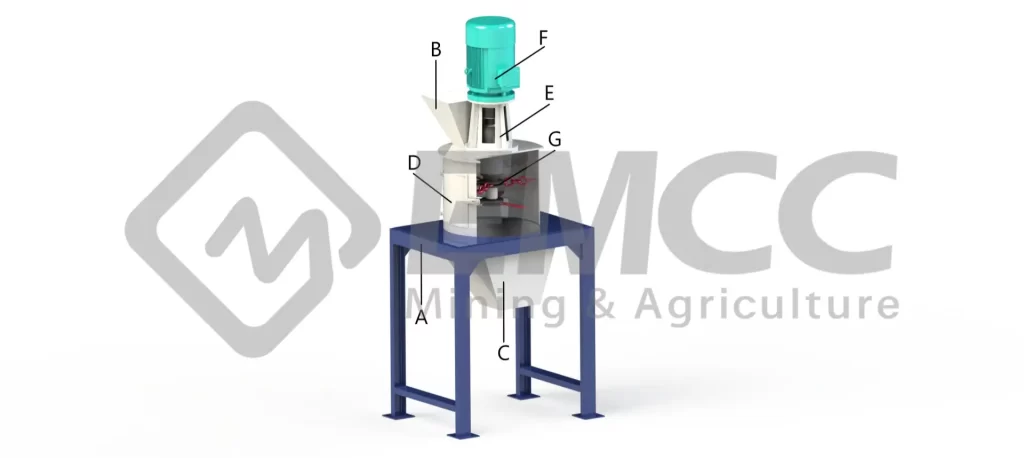

THE VERTICAL CHAIN CRUSHER

The vertical chain crusher has a single rotor structure, which is composed of a cylindrical shell, a rotor and upper and lower support bearings.

WORKING PRINCIPLE

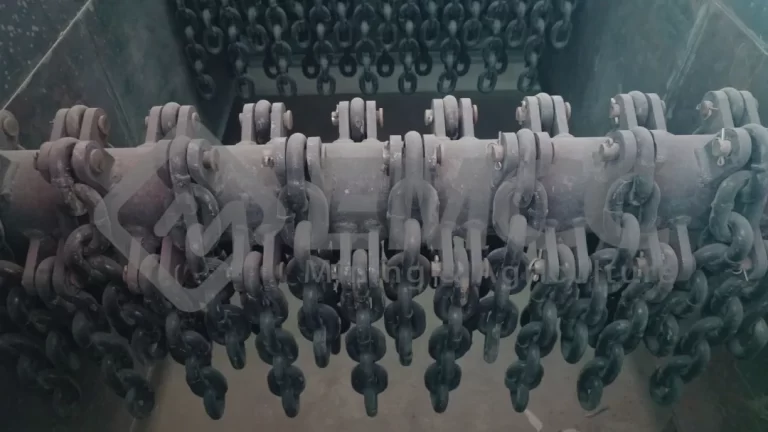

There is a feed inlet on the shell upper part. 2-5 chain disks are installed on the rotor, and a number of chains are hung on each chain disk (sometimes chains can be replaced by blades according to the situation), the chains are staggered between the upper and lower layers. When the material enters from the feed inlet, it is hit by the rapidly rotating chain, and then hits the cylinder wall and each other and is crushed.

FEATURES

The number of chains can be increased or decreased as needed.

Compact structure and smooth operation.

Easy maintenance.

VERTICAL CRUSHER COMPONENTS

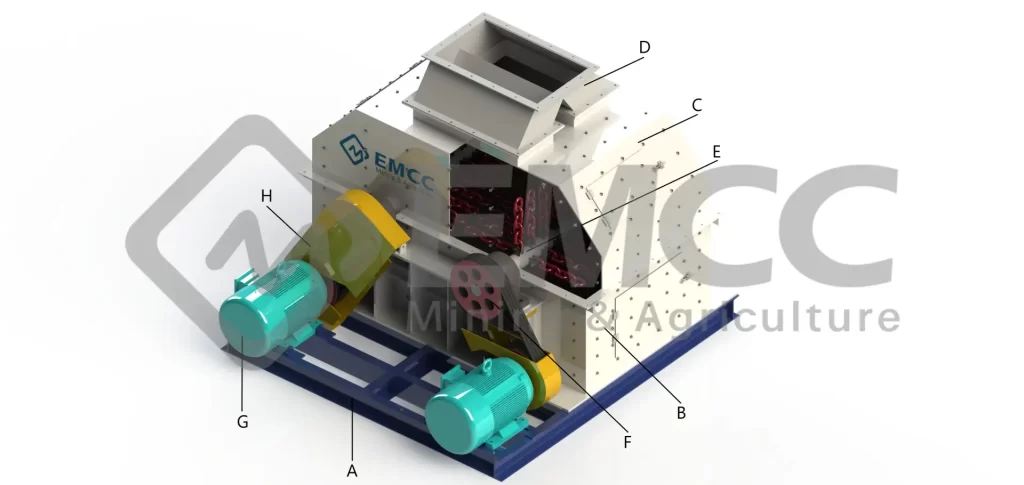

THE HORIZONTAL CHAIN CRUSHER

The horizontal chain crusher has a double-rotor structure, consisting of two parallel rotors arranged horizontally. Each rotor is equipped with same number of chain groups, and the number of chain links in each chain group is equal.

WORKING PRINCIPLE

There is a feed inlet on the shell upper part. When the material enters chain groups from the feed inlet, it is hit by the rotating chain, and then collide with each other at a high tangential speed insides the shells and is crushed. The crushed material is discharged from the lower discharge port.

FEATURES

Compared with vertical chain crushers, horizontal chain crushers are less likely to be clogged.

High crushing efficiency, continuous work.

Easy maintenance.

HORIZONTAL CHAIN CRUSHER COMPONENTS

Photos

RESOURCES

WHY CHOOSE DOUBLE SHAFT CHAIN CRUSHER

The double shaft chain crusher is a professional crushing equipment

MULTIPLE SPECIFICATIONS OF HIGH MOISTURE CRUSHER

The high moisture fertilizer crusheris is a new type of crusher, which