Conveying Equipment

EMCC offers reliable machinery that meets high standards in design and material selection to ensure continuity in your production process

CONVEYING EQUIPMENT

In the fertilizer production line, the supply of raw materials, the transfer of semi-finished products and the transportation of finished products, packaging, etc. all require corresponding conveying equipment.

Conveying equipment and systems may not seem like the main production equipment, but they play a vital role in the operation of the production line. Conveying equipment and systems can be the main obstacle to a production line’s uptime, and when properly designed, it can also be its most valuable asset.

In the process of pre-sales communication, EMCC will fully communicate with the user, and better integrate with other buildings of the factory through 3D modeling.

INFLUENCING FACTORS

The choice of conveying equipment and systems has a lot to do with the characteristics of the material that is usually designed:

- Loose density, loose angle, moisture content, temperature, etc.

Factors such as the production environment should also be considered:

- Estimated plant area or existing plant area, surrounding size restrictions, requirements for walkways, maintenance platforms, etc.

ADVANTAGE

With properly designed equipment, line operations and plant managers will benefit greatly:

- Optimize line efficiency

- Higher yields.

- Better process control.

- Reduced labor requirements.

- Improve security.

- Reduced housekeeping.

- Reduce downtime for troubleshooting and maintenance.

- Extend the life of your equipment.

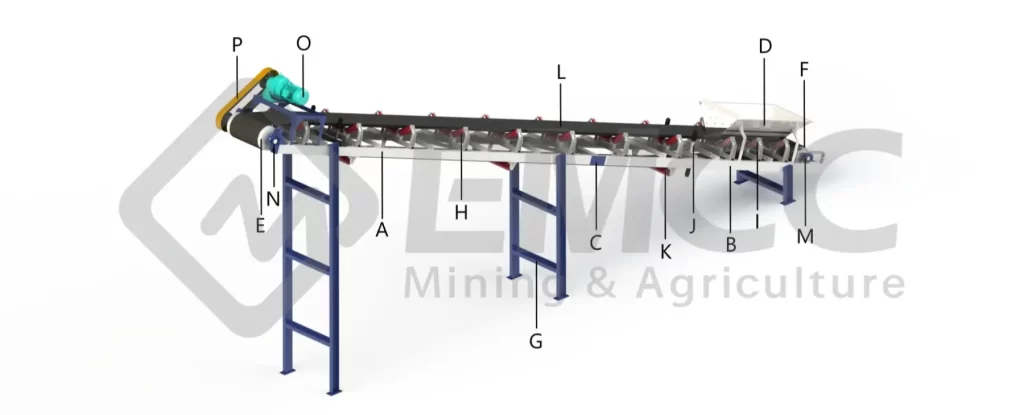

BELT CONVEYOR

The belt conveyor transportation distance can be long or short, the assembly is flexible, the structure is simple, the operation is convenient, the power consumption is low, the main components are shown in the figure below.

A – Head frame

B – Tailstock

C – Main frame connection plate

D – General assembly of guide trough

E – Drive pulley

F – Bend pulley

G – Leg

H – Trough type roller set

I – Buffer roller set

J – Deflection roller

K – Parallel lower roller set

L – Belt

M – Bearing with slide block

N – Vertical seat bearing

O – Motor

P – Protecting cover

BUCKET ELEVATOR

Bucket elevator is a vertical conveying and transportation equipment that is widely used in the production line. The main components are shown in the figure below.

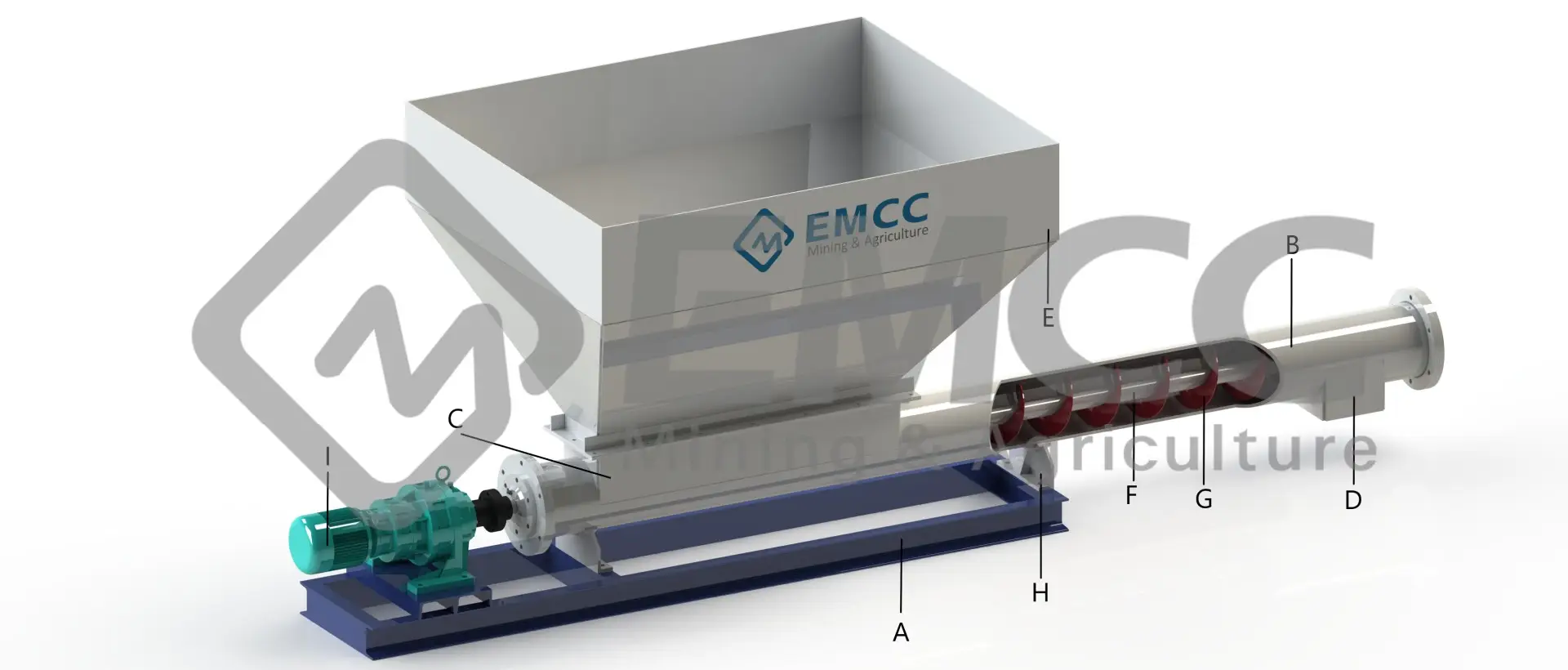

SCREW CONVEYOR

Screw conveyor is a kind of equipment that uses a motor to drive the screw to rotate and move materials to achieve the purpose of conveying.The main components are shown in the figure below.

Photos

RESOURCES

Fertilizer Coating Technology

The crop nutrition industry is being challenged to produce fertilizers

EMCC Has Participated European Exhibition

The European International Agricultural Exhibition, was successfully held in Nov. 2025. For