Mixer

EMCC offers reliable machinery that meets high standards in design and material selection to ensure continuity in your production process

MIXER

The stirring and mixing of fertilizer raw materials refers to the fact that under the action of external force, the raw materials are mixed from the initial whole mixture in the mixer to the state of full mixing. In the production process of compound fertilizer, whether the mixing and stirring of raw materials is uniform directly affects the product quality and application effect of the final fertilizer.

Twin shaft horizontal mixer is one of the important equipment used in the process of fertilizer granulation. It adopts a biaxial design, which can mix various raw materials more evenly and ensure the quality and stability of fertilizer pellets.

Twin-shaft horizontal mixers are usually equipped with a highly efficient mixing unit and adjustable speed to meet the needs of different fertilizer manufacturing processes. At the same time, it also has the characteristics of compact structure, easy operation and easy maintenance, and is one of the indispensable key equipment in the fertilizer production line.

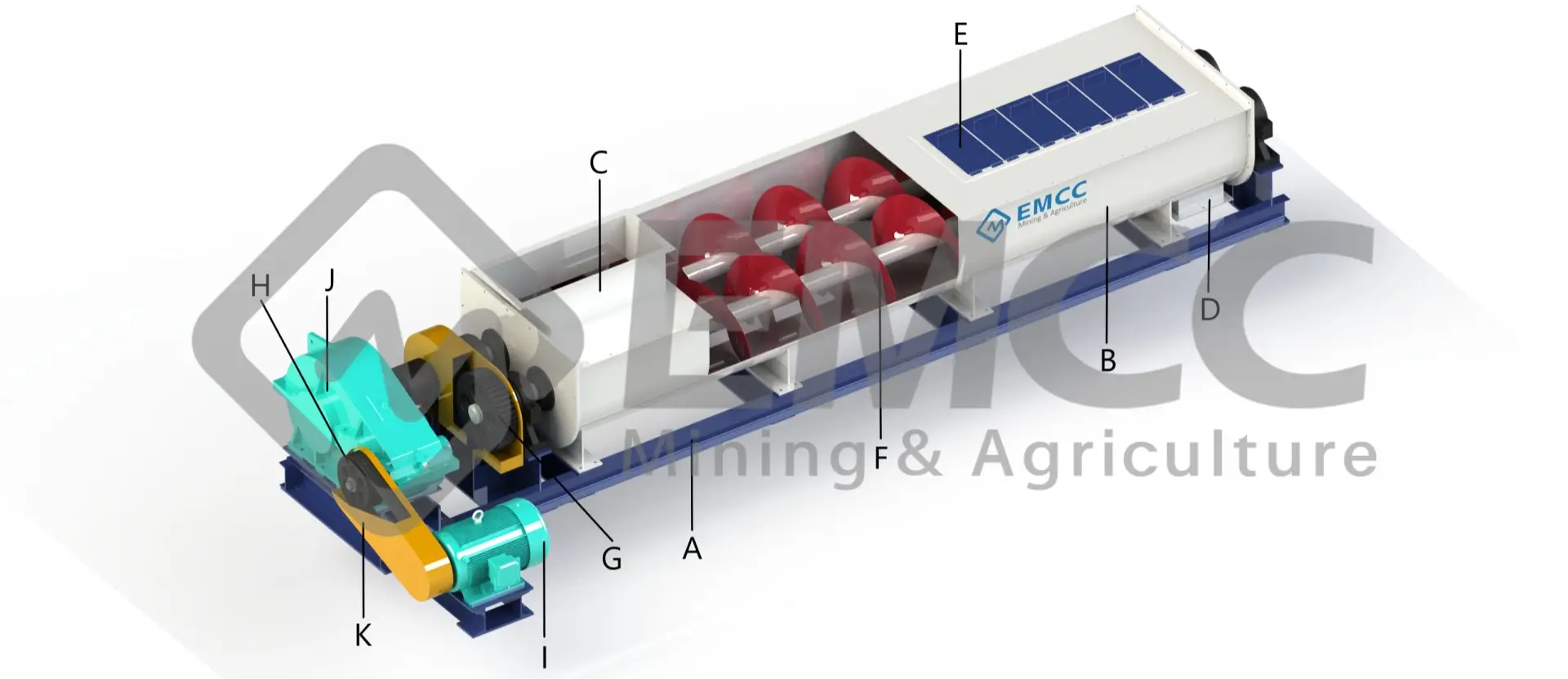

The twin-shaft mixer uses the synchronous rotation of two symmetrical spiral shafts, which is mainly composed of casing, spiral shaft assembly, driving device, piping, cover, chain cover and other components.

FEATURES

The shell is mainly made of plates and sections, welded and formed, and assembled with other components to support the twin-shaft mixer. The shell is tightly sealed, and there will be no fly ash outward.

The screw shaft assembly is the main component of the twin-shaft mixer, and its components mainly include left and right rotating screw shafts, bearing seats, bearing sleeves, bearing covers, gears, sprockets, oil cups, blades and other parts. The manufacturing precision of the left and right rotary spiral shafts is high, the process performance is good, and there are strict matching requirements with bearing seats, bearing sleeves and bearing covers. The gears and sprockets are protected by protective covers, which can operate safely and effectively.

The material of the blades of the twin-shaft mixer is made of materials that are resistant to wear and do not stick to ash. The blade structure is designed to be reasonable and simple, easy to replace after wear, and has a long service life.

DOUBLE-SHAFT HORIZONTAL MIXER COMPONENTS

Photos

RESOURCES

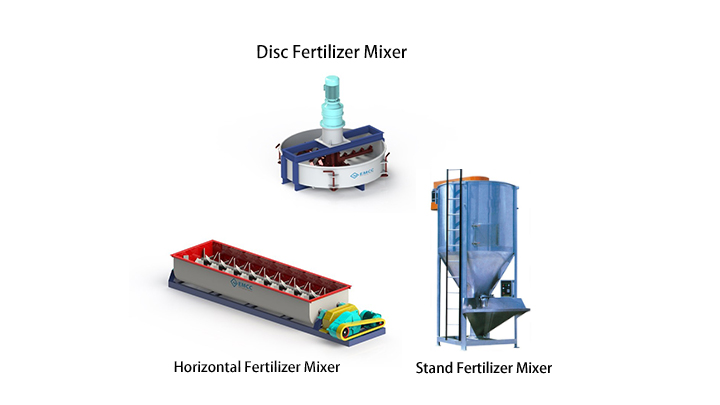

CLASSIFICATION OF ORGANIC FERTILIZER MIXERS

The vertical disc mixer is a special mixer for the

WHAT ARE THE TYPES OF ORGANIC FERTILIZER CRUSHERS

Our company’s main products are 1-20 tons of organic fertilizer,