The fertilizer granulation process turns fine powders into uniform, solid granules for easier application and to ensure consistent particle size, improve nutrient distribution, prevent caking, and control nutrient release for better agricultural performance.

Benefits of Granulation

Improved Handling: Easier to spread evenly with mechanical spreaders.

Consistent Application: Uniform particle size ensures even nutrient distribution.

Reduced Nutrient Loss: Less runoff and leaching compared to powders.

Controlled Release: Coatings can make fertilizers slow-release.

EMCC FERTILIZER GRANULATION LINES

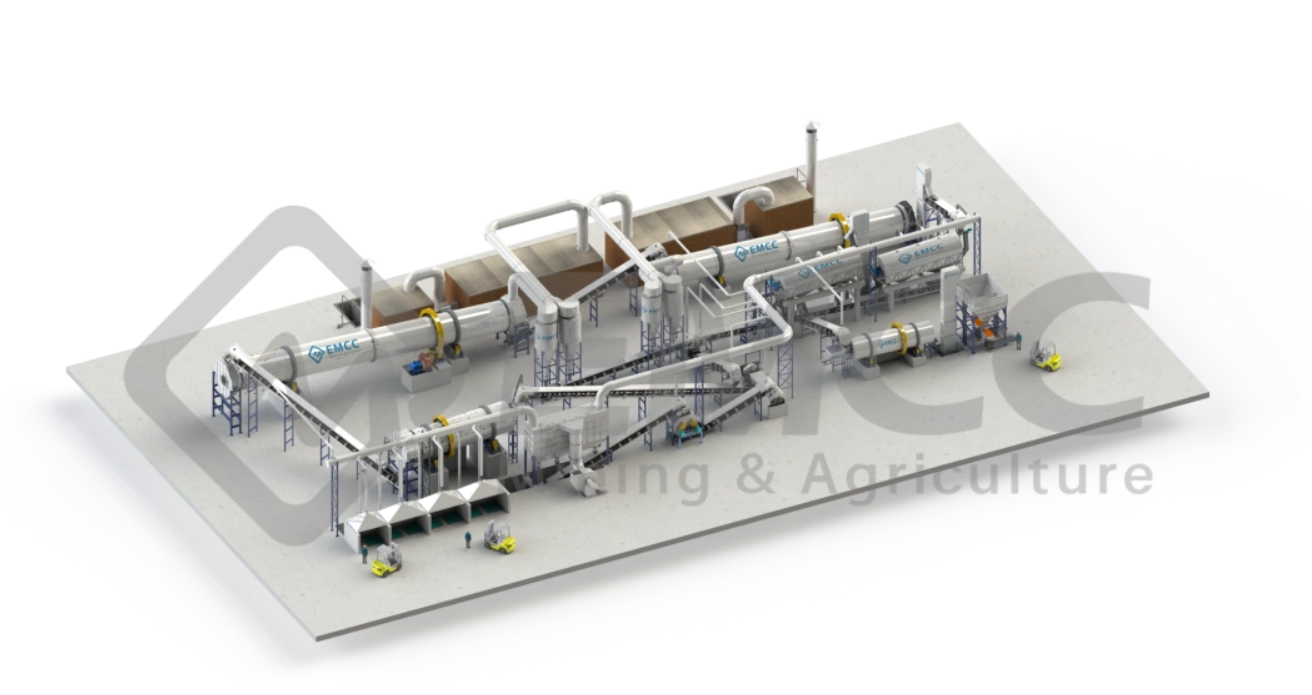

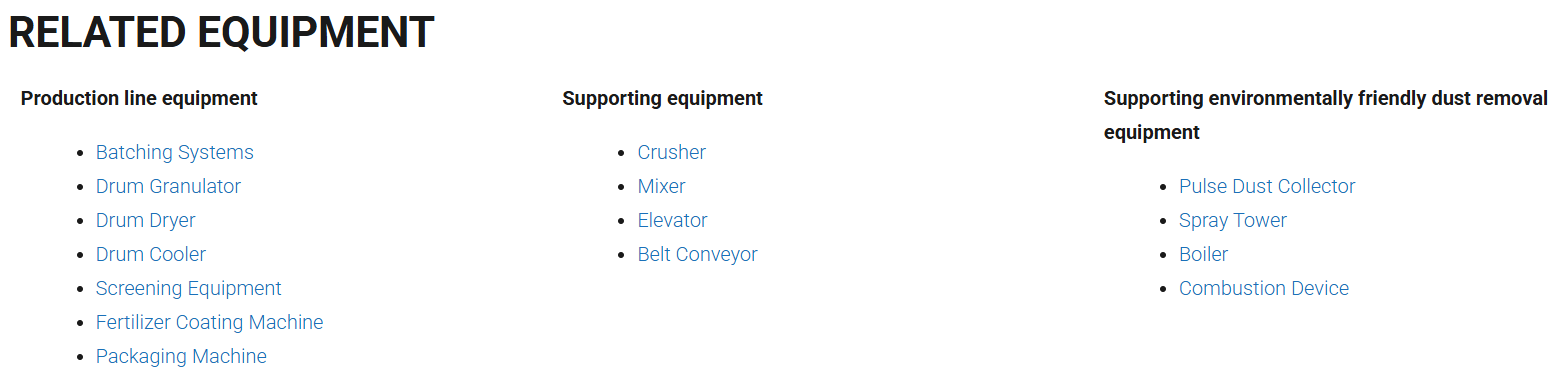

ROTARY DRUM GRANULATION PRODUCTION LINE

The rotary drum granulation production line is characterized by its large single unit production capacity and closed design. At the same time, it can use steam to add water and increase the temperature during the granulation process, so that it can reduce the energy consumption of the subsequent dryer process, to a certain extent.

Generally, the process flow is: fertilizer raw materials batching–pretreatment & crushing–mixing–granulation–drying–cooling–screening & return–coating–packaging–finished product.

ROTARY DRUM GRANULATOR MAKING LINE IS AN IMPORTANT TECHNICAL MEANS OF WET GRANULATION PRODUCTION LINE

Wet granulation is the most widely used technology in fertilizer granulation production lines. It is widely accepted because of its wide applicable scope of raw materials, high production efficiency, good granular shape and high strength after drying.

The rotary drum pelletizer production line is mainly used for the granulation of phosphorus compound fertilizers, such as monoammonium phosphate(MAP), diammonium phosphate(DAP), nitrogen-phosphorus-potassium compound fertilizers(NPK), heavy calcium superphosphate and many other products(TSSP). It is also used for ammonia granulation.

Meanwhile, rotary drum pellet making line is also widely used in the production of organic and inorganic compound fertiliser.

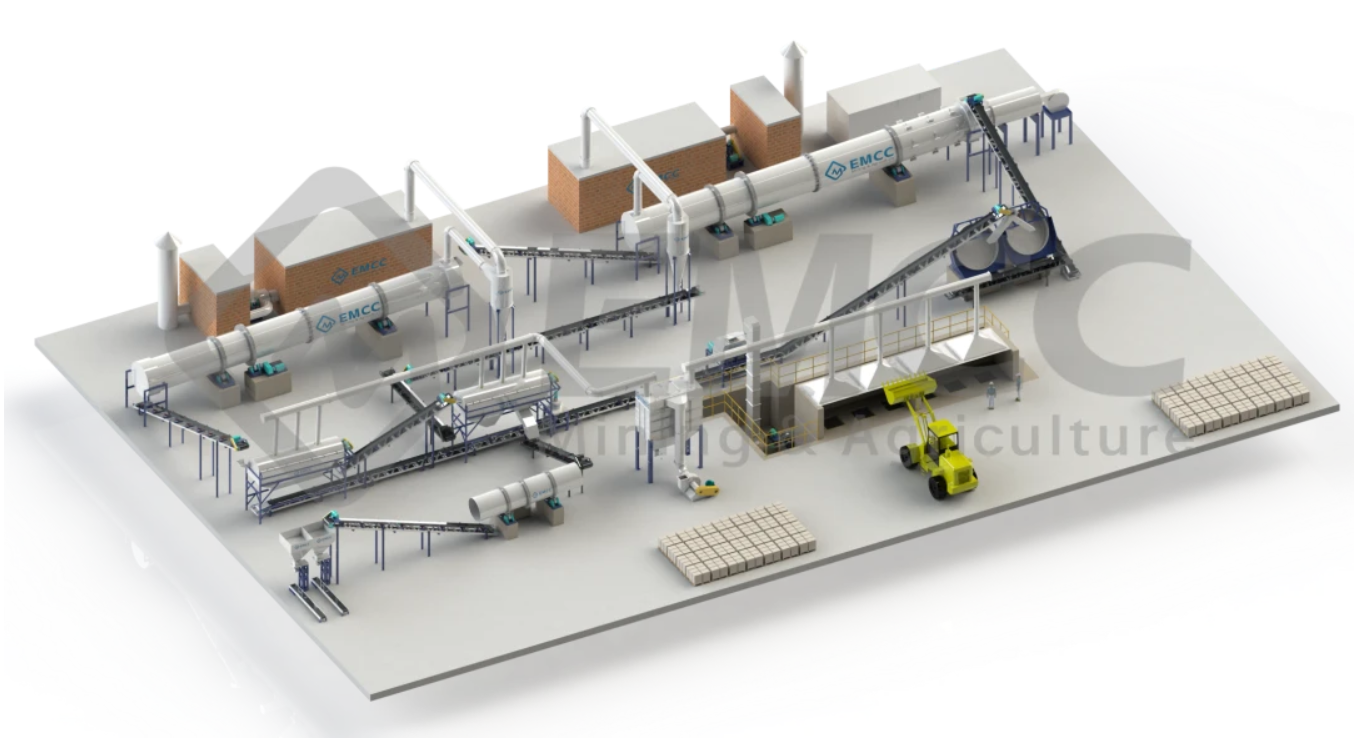

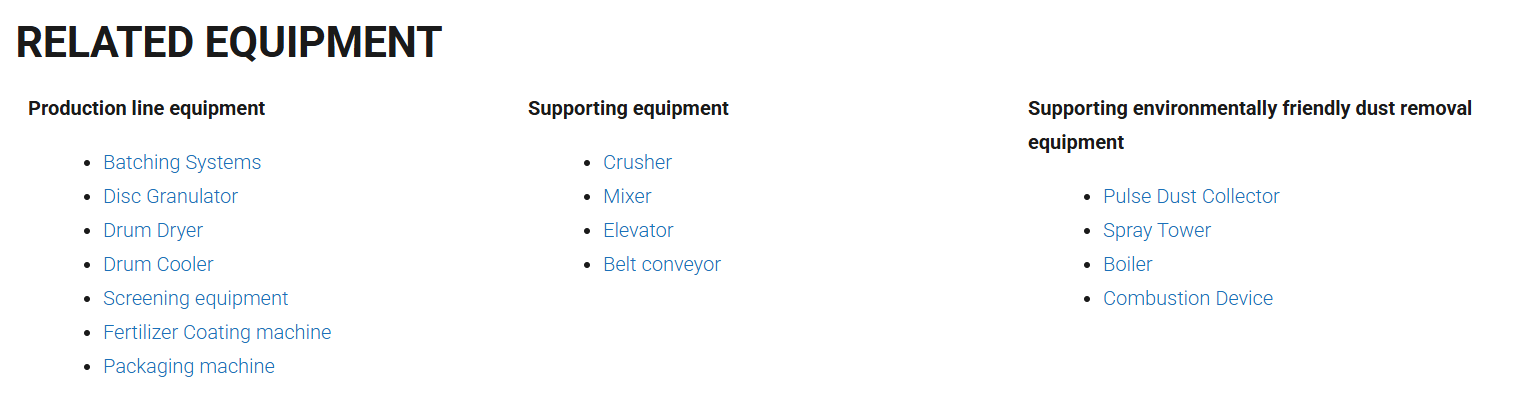

DISC GRANULATION PRODUCTION LINE

The disc granulation production line is characterized by its simpler operation, less material return, and higher granulation ratio.

Generally, the process flow is: fertilizer raw materials batching–pretreatment & crushing– mixing–granulation–drying–cooling–screening & return–coating–packaging–finished product.

DISC GRANULATION PRODUCTION LINE IS AN IMPORTANT TECHNICAL MEANS OF WET GRANULATION PRODUCTION LINE

Disc granulator making line is the most commonly used technical means in fertiliser granulation production line, which is not only capable of producing compound fertiliser, but also pure organic fertiliser.

Pan pelletizer production line produces uniform particles, with good automatic grading ability, in the granulation at the same time can also add liquid, high granulation efficiency, generate fewer large particles, less return material. And disc granulation production line operation is intuitive and simple, easy to control, the formula can also be changed flexibly.

PRESSURE ROLLER GRANULATION PRODUCTION LINE

The pressure granulation production line is suitable for some specific raw materials. Because it only needs to add a small amount of water during the extrusion granulation process, which will greatly reduce the drying energy consumption of the subsequent process, and even some raw materials do not need to be dried after granulation.

EXTRUSION ROLLER GRANULATOR PRODUCTION LINE IS ALSO CALLED DRY PRESSURE PELLETISING PRODUCTION LINE

Extrusion Roller Granulator Making line (Pressure Pelletizer): the raw material from the hopper continuously and uniformly added to the top of the roll, in the continuous rotation of the roll extrusion effect, the powder is extruded into plate, and then in the centrifugal effect and the effect of the plate’s own gravity off, in the crushing function with the impact of the shaping wheel is separated into particles.