Phosphate rock (PR) is used to produce the majority of acidulated phosphate fertilizers used throughout the world, but it can also be used for direct application with little processing. Unlike the essentially uniform acidulated fertilizer products made with PR, the PR itself can vary greatly in composition depending on certain factors.

Some specimens are so ineffective that they should be avoided for direct application in crop production; others, however, can provide plants with phosphate as effectively as the more costly acidulated sources.

Concept of DAPR

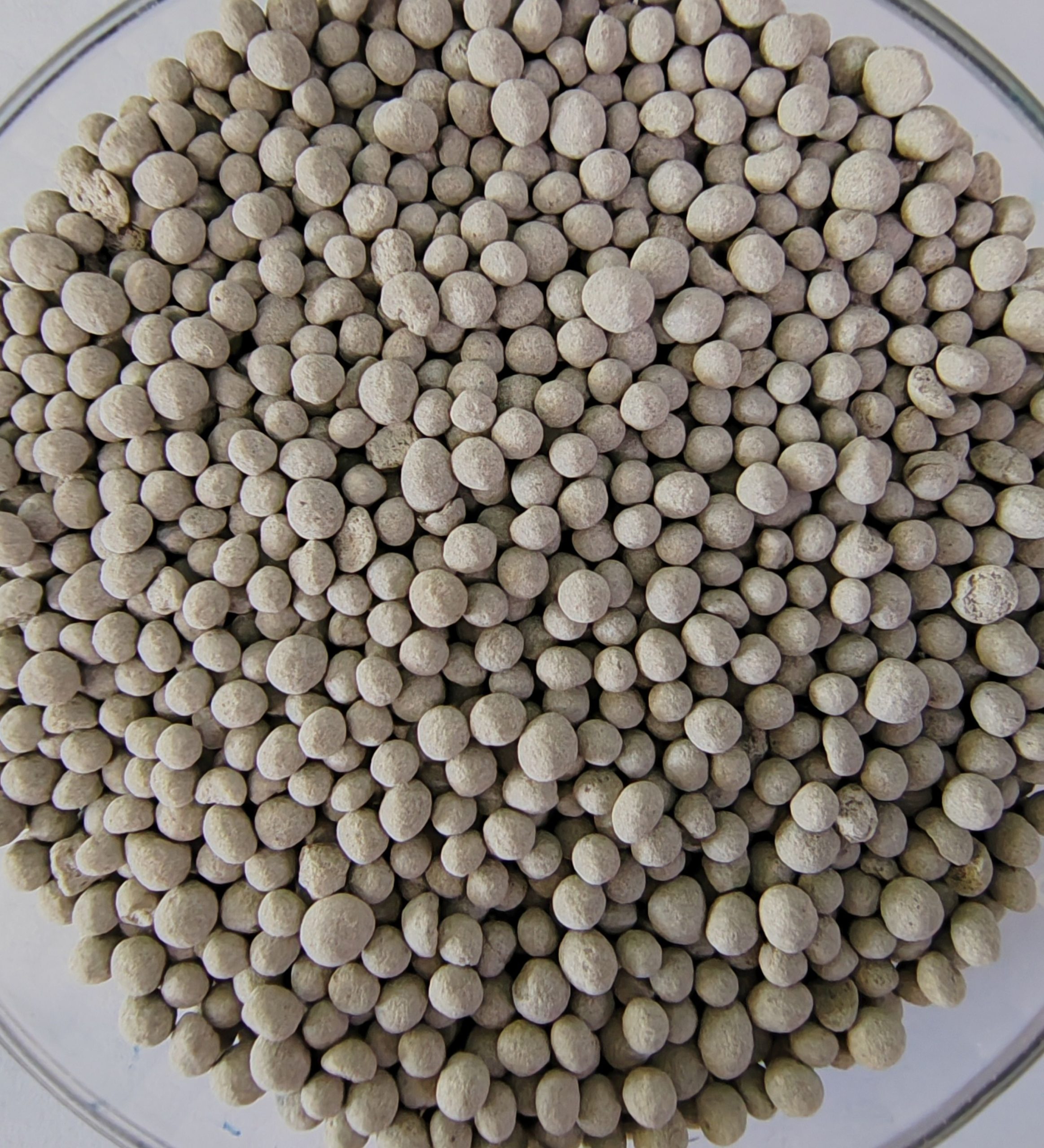

DAPR generally involves grinding the PR until at least 80% passes through a 100-mesh sieve, and then applying it directly to the soil. Production of this phosphate (P) source requires only physical processing without any chemical treatment of the rock.

The primary mineral in PR is called apatite, which may exist in a variety of chemical formulas. Due to natural differences in the chemical and mineralogical composition of its crystals, the resulting apatite minerals may feature a vast range of reactivity, solubility, and agronomic effectiveness, with some being excellent phosphate fertilizers for commercial crops when applied directly while others are not.

How to know whether a DAPR will be highly effective?

Agronomic studies have shown that about 80% of PR effectiveness is determined by just three factors: the type of apatite in the PR, the soil pH, and the crop being grown. Other factors include the crop, specific soil conditions, PR and soil management, and more.

Given this myriad of factors, estimating the agronomic effectiveness of PR can be complex. This is why the freely accessible Phosphate Rock Decision Support System (PRDSS) model can be used to assist with these calculations. The PRDSS evaluates the quality of PR for direct application using laboratory solubility methods that help determine how effectively the PR will provide phosphate to crops.

It is also important to note that DAPR should be conducted in specific way to maximize effectiveness: PR should be applied in powder form at the soil surface, followed by incorporation, preferably to 20 cm soil depth.

Can low-reactivity PR be used for direct application?

PR with low reactivity should not be utilized without some type of treatment. The most common approach is acidulation, which converts PR into highly water-soluble compounds readily available to plants. While acidulation is by far the most widely used method for producing P fertilizers, it is also expensive.

Modified PR fertilizers, such as partially acidulated phosphate rock (PAPR) and compacted fertilizers, offer alternative approaches. In partial acidulation, smaller amounts of acid are used as compared to the amounts needed for complete acidulation, while compacted fertilizers are produced by blending PR with an acidulated P fertilizer, such as triple superphosphate.

Both PAPR and compacted fertilizers can provide good agronomic and economic results in many circumstances, especially in resource-limited countries where importing high-grade phosphate is costly and/or challenging. The right choice of PR technology is case-specific, and preliminary research is necessary to determine whether a modified PR fertilizer is feasible and, if so, which type would be most effective.