News

EMCC has been delivering custom process equipment, process development services, and service support to companies internationally for over 10 years.

WHAT TYPES OF ORGANIC FERTILIZER COMPOST TURNERS ARE THERE

The compost turner is divided into two types: the compost turner that can walk on the ground and the trough compost turner that works on the fermentation tank.

THE DETAILED PROCESS OF PRODUCING LIVESTOCK MANURE ORGANIC FERTILIZER BY DRUM GRANULATION PROCESS

1. Transport the treated poultry manure (cattle, sheep, chicken manure, etc.) directly to the raw material mixer; 2. Transported to the drum granulator, and steam (or water) is introduced at the same time. The material forms a rolling material bed by the friction generated by the rotation of the drum granulator, and the extrusion force generated by rolling makes it contain a certain liquid phase. The materials agglomerate into small particles, these small particles become the core, and adhere to the surrounding powder to form qualified particles; 3. Transport to the organic fertilizer dryer for heat exchange with the heat from the hot blast stove; 4. Transported to the hot

MAINTENANCE OF DRUM GRANULATOR

Rotary drum granulator is one of the key equipments in the compound fertilizer industry, suitable for hot and cold granulation and large-scale production of high, medium and low concentration compound fertilizers. 1. Bracket part The rotating part of the whole fuselage is supported by the bracket, which bears a lot of force. Therefore, the supporting wheel frame part of the machine is welded by medium carbon steel plate and channel steel, and has passed strict quality control and special process requirements to meet the production standard of this machine. In addition, it is more important to fix the rollers on the shelves. Taking into account the large friction with the

INSTALLATION AND TEST POINTS OF DISC GRANULATOR

Disc Granulator is a kind of granulator, the granulation success rate can reach more than 93%. The application of this machine greatly reduces labor intensity and improves labor efficiency. 1. Specific installation points: 1) The equipment should be installed on a level concrete foundation and fixed with anchor bolts. 2) Pay attention to the verticality of the main body and the horizontal when installing. 3) After installation, check whether the bolts in each part are loose and whether the door of the main engine is fastened. If so, please fasten it. 4). Configure the power cord and control switch according to the power of the equipment. 5) After the

STRUCTURAL DESIGN OF DOUBLE SHAFT FERTILIZER MIXER

The double shaft fertilizer mixer is a new generation of mixing equipment developed by our company. This machine can fully mix the raw materials, and after the machine operation is completed, there will be no raw materials sticking to the inner wall of the machine. It is suitable for mixing organic fertilizers and inorganic fertilizers. Specific features: 1. The materials are fully mixed, thereby improving the uniformity of mixing; 2. The gap between the rotor and the casing can be adjusted to near zero by adopting a novel rotor structure, which effectively reduces the residual amount of materials; 3. The special rotor design of the machine can also crush larger materials.

MULTIPLE SPECIFICATIONS OF HIGH MOISTURE CRUSHER

The high moisture fertilizer crusheris is a new type of crusher, which is highly adaptable to materials with high moisture content, especially for fermented livestock and poultry manure, municipal waste or other materials with a moisture content of ≤30%. The particle size of the powder can reach 20 mesh to 30 mesh, which can meet the feed particle size requirements of general fertilizer granulation equipment, and the surface of the produced particles is smooth. We can provide various specifications of equipment, and at the same time, we can also provide you with equipment customization services. Fully meet the various production needs of customers.

THE DEVELOPMENT HISTORY OF VERTICAL CHAIN CRUSHER

Compound fertilizer is the fastest growing fertilizer variety in my country in recent years. In the production of powdery and granular phosphate fertilizers and compound fertilizers, the selected crusher is mainly used for the crushing of raw materials and large and large semi-finished products, especially suitable for superphosphate, heavy superphosphate, compound fertilizer, ammonium phosphate, nitro Phosphate fertilizers, etc. typical. These materials are easy to absorb moisture and have high viscosity. In the crushing process, they are easy to stick to the inner wall of the casing, causing the machine to block, frequent shutdowns for cleaning, and the material stuck to the inner wall of the casing is hard and difficult

HOW TO DEFINE AND CALCULATE THE NUMBER OF ROTARY DRUM SCREEN

Rotary Drum Screen is a commonly used organic fertilizer material screening equipment. When we use Rotary Drum Screen, the selection of the screen is very important. Then, how to choose the right screen? The screen is an important part of the screening machine, which is made of mulberry silk, metal wire or synthetic fiber. The screen has the advantages of precise weaving, zero defects, regular mesh, reliable filtration accuracy, high compressive strength, high temperature resistance, chemical corrosion resistance, and good wear resistance. The screen is a non-standard product, and the size of the vibrating screen, the number of layers of the screen, and the mesh number of the screen can

INTRODUCTION OF TYPES AND FUNCTIONS OF ORGANIC FERTILIZER MIXERS

When producing organic fertilizers, we will come into contact with a variety of organic fertilizer raw materials. The properties of each material are different, and the mixers that need to be used are also different. In terms of the types of organic fertilizer mixers, they can be divided into horizontal mixers and vertical mixers in terms of appearance; in principle, they can be divided into single-shaft mixers and double-shaft mixers, but no matter how their styles change, their functions are the same. It relies on the main shaft to drive the blades to stir the material. For a fertilizer production line, its raw materials can be organic fertilizers or inorganic

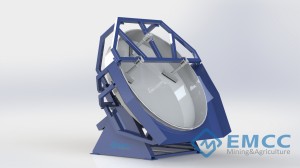

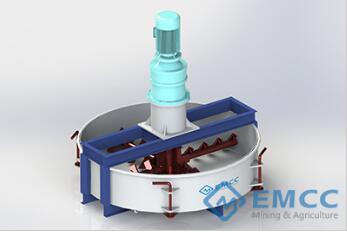

The use and advantages of disc organic fertilizer mixer

The disc type organic fertilizer mixer is a special mixer for the fertilizer industry. It is a kind of mixing equipment specially used for organic fertilizer mixer produced by our company. It is characterized in that a cylinder is arranged in the center of the stirring plate, a cylinder cover is arranged on the cylinder, the stirring arm is fixedly connected with the cylinder cover, the end of the stirring shaft connected with the cylinder cover passes through the cylinder body, and the stirring shaft drives the cylinder. The cover rotates, thereby driving the stirring arm to rotate to achieve uniform mixing of materials. Features: 1. The disc type organic

What wrong behaviors will reduce the efficiency of BB fertilizer

BB fertilizer, also known as formula fertilizer, is a high-quality and high-efficiency compound fertilizer composed of three or more single-grain fertilizers, namely nitrogen, phosphorus, potassium or other elements. As a physicochemical technology of formula fertilization, BB fertilizer is conducive to accelerating the popularization and application of formula fertilization technology in rural areas. Places that should be paid attention to during fertilization 1. Pay attention to moisture-proof to prevent nitrogen volatilization or agglomeration. 2. Pay attention to uniformity. If there is delamination, it should be shaken up and down; in case of agglomeration, use a wooden stick or a wooden hammer to smash it before use, otherwise the unevenness will affect

THEPERFORMANCE CHARACTERISTICS OF THE STIRRING TOOTH GRANULATOR

The organic fertilizer stirring granulator newly developed by EMCC is a molding machine that can make materials into specific shapes. (1). The principle is simple and the granulation speed is fast. The mechanical stirring force of high-speed rotation and the resulting aerodynamic force are used to continuously realize the mixing, granulation, spheroidization and densification of fine powder in the machine, so as to achieve the purpose of granulation. (2). With high granulation quality, the machine is especially suitable for granulation of light fine powder materials. The finer the basic particles of fine powder materials, the higher the sphericity of particles and the better the balling quality. (3). No binder is

PROCESS FLOW OF ORGANIC FERTILIZER PRODUCTION LINE OF DISC GRANULATOR

Disc granulator is a common tool for organic fertilizer granulation. The specific production process is as follows: (1) Crushing and mixing: The fermented and decomposed animal powder organic fertilizer raw materials are crushed to make them reach the appropriate particle size, and then transported to the horizontal mixer for mixing, and then transported to the granulator to feed the bin. (2) Feeding and granulation: the powdery raw materials are evenly fed through the feeding bin, and fed into the disc of the disc granulator at a uniform speed; according to the moisture condition of the material, it is sprayed on the disc by the automatic moisture shower of the disc

HOW A TUMBLE DRYER WORKS

The rotary drum dryer is mainly composed of a heating source, a feeder, a feeder, a rotary drum, a material crushing device, a discharging machine, an induced draft fan, a discharger and a power distribution cabinet; Working Principle:The wet material after dehydration is added to the dryer Then, under the turning of the evenly distributed plate copying device in the drum, the material is evenly dispersed in the dryer and fully contacted with the hot air, which speeds up the heat and mass transfer of the drying. In the drying process, under the action of the inclined board and the hot temperament, the material is discharged to the star-shaped discharge

THE INTERNAL DUST REMOVAL DESIGN OF THE SCRUBBER

Scrubber is a new type of waste gas treatment equipment, which is widely used in the pretreatment of industrial waste gas purification and dust removal, so as to purify the air, and the purification effect is very good. A certain height of packing layer is set inside the scrubber, and a spraying system is set from the upper part of the tower body, and the uppermost section is the demisting system. It uses the contact between gas and liquid to transfer the pollutants in the gas to the liquid, and then separate the clean gas from the polluted liquid to realize gas treatment. Firstly, the harmful waste gas enters from the

HOW DOES THE AUTOMATIC PACKAGING MACHINE PERFORM DUST-FREE AUTOMATIC PACKAGING

The emergence of the automatic packaging machine is to replace the labor of bagging, which can help enterprises reduce labor and realize automatic packaging. It occupies a small area and has strong practicality. It can realize functions such as automatic bagging, automatic weighing, automatic filling, automatic sealing and automatic package delivery. Unmanned operation of transportation and automatic palletizing. How does the automatic packaging machine perform dust-free automatic packaging? First, put the packaging bag into the bag collection box. After the automatic bagging packaging system is activated, the vacuum suction cup above the bag mouth of the packaging bag will drop rapidly under the action of the air cylinder, suck the

WHAT SHOULD BE PAID ATTENTION TO IN THE SELECTION OF HEAT SOURCE FOR ENERGY-SAVING PIG MANURE ORGANIC FERTILIZER DRYER?

The selection of heat source is very important for pig manure organic fertilizer drying equipment, not only to ensure the problem of meeting the emission standards, but also to consider the operating cost. Buying a suitable heat source can increase the actual effect of drying and greatly reduce the operating cost of the pig manure organic fertilizer drying equipment. As an energy-saving pig manure organic fertilizer drying equipment, what should people pay attention to when choosing a heat source? 1. Ensure the dry quality of pig manure. The quality of the finished product determines the quality of the energy-saving pig manure organic fertilizer drying equipment. Excellent heat source and calorific

WHAT IS THE ACTUAL PRODUCTION PROCESS OF BB FERTILIZER?

At the beginning of the BB fertilizer equipment’s development and design, EMCC fully considered the practicality and work efficiency, and carried out a unique design of the machine, which can fully meet the requirements of large-scale continuous production. It is your first choice for purchase. BB fertilizer manufacturing process: microcomputer control → belt scale continuous batching → large batch continuous mixing and discharging → automatic packaging → finished product. ①Batching system: Automatic arc gate feeding device(arc gate feeding is two-stage feeding, which can accurately meet the proportion of materials). Static metering hopper metering (static metering hopper metering is a more practical and advanced metering method, batching speed is fast, the measurement

GRANULATION STEPS OF DOUBLE ROLL FERTILIZER GRANULATOR

The double roller fertilizer granulator is a newly developed granulator in the fertilizer industry. This equipment can form fertilizer particles with a diameter of 1-4mm at one time, and the granulation rate is as high as 85%, which can bring good economic benefits to fertilizer investment. The granulation process of double roller fertilizer granulator is divided into two parts: extrusion process and granulation process. The dried material is compressed into a hard and dense block under pressure, which is the extrusion process. The function of pressure is to squeeze the air between the particles so that the distance between the particles is close enough to generate an interaction force.The block material is crushed, sieved

MANUAL OF DOUBLE SHAFT FERTILIZER MIXER

The horizontal fertilizer mixer is a new generation of mixing equipment developed by our factory, with high mixing uniformity and less residual material. This kind of fertilizer mixer is suitable for compound feed, concentrated feed, additive premix, organic fertilizer, compound fertilizer and other raw materials. Notes on using the machine: 1. Be sure to check whether the bolts are loose before starting the machine. 2. Check the bearing seat and reducer. See if their oil levels are in place. 3. It is strictly forbidden to mix with large stones, large iron and other materials, so as not to damage the stirring blades. 4. Stop feeding before shutting down. It prohibits

TAKE YOU TO UNDERSTAND THE DISC GRANULATOR

The disc granulator produces granules by continuously rotating the disc. The small series is driven by the motor to drive the reducer and then directly drives the disc to rotate, while the larger series is driven by the main motor to drive the pulley and belt, and the small gear is driven by the reducer. The small gear and the large gear fixed on the bottom of the disk mesh with each other, and work in opposite directions.The big gear is specially designed to be installed on the main shaft ,fixed on the frame adjustment plate to support the work of the entire pelletizing plate. Equipment advantages: 1. The angle

HIGH MOISTURE FERTILIZER CRUSHER MACHINE

The crushing of high moisture materials has always been a headache for major crushing plants, because most of the materials will be blocked on the screen and it is easy to burn the motor. Therefore, there is an urgent need for a device that can pulverize high moisture materials to solve this problem. Don’t worry, this is coming soon – high moisture materials crusher, this high moisture materials crusher is upgraded from the old-fashioned crusher, and it has a very good crushing effect on high-moisture materials like straw. 1.The machine can be divided into three parts: (1). Frame part: The normal operation of all machinery is inseparable from a solid frame.In

NEW COATING MACHINE—SULFUR COATING

The sulfur coating controlled release complete set of equipment is a new environmental protection process, which wraps the molten sulfur on the surface of urea particles and the sealing material, and is a coated fertilizer with slow-release effect. Sulfur coated urea generally contains 10% – 30% sulfur. Sulfur is not only a medium nutrient element second only to N \ P \ K in crop demand, but also has many functions, such as sterilization, improving soil and increasing soil permeability.

TOWER FERMENTATION MACHINE

The livestock and poultry manure tank fermentation machine adopts the principle of aerobic fermentation, using the organic matter, residual protein and microorganisms in the livestock and poultry manure, and under a certain temperature and humidity, the organic matter and protein in the manure are used as food for rapid reproduction. and sufficient oxygen; they consume organic matter, proteins, and oxygen, and metabolize to produce ammonia, carbon dioxide, and water vapor. At the same time, a large amount of heat is released to increase the temperature in the tank, 45 ° C ~ 60 ° C promotes the growth and metabolism of microorganisms, and above 60 ° C can kill harmful

FERMENTATION DRUM MACHINE

The fermentation tank device is composed of a cylinder body, a sealing system, a feeding and discharging system, a supporting wheel group and a blocking wheel group, an air supply, and an exhaust gas treatment system.: The cylinder rotates on the roller set through the driving system; the material is controlled by the feeding and discharging system; the drum sealing system is designed with double sealing to ensure no water vapor and odor release; the water vapor and odor after fermentation are sent by the negative pressure exhaust system to the exhaust gas treatment system for treatment. Equipment advantages: 1) The fermentation drum device has the function of continuously and

WASTE GAS TREATMENT EQUIPMENT

This equipment is used to deodorize the waste gas generated in the process of waste processing by biological bacteria, and discharge the waste gas after it meets the national standard. This equipment is the first choice for livestock manure and fertilizer processing enterprises.

SLUDGE GARBAGE DECOMPOSITION TREATMENT EQUIPMENT

The sludge fertilizer making equipment extracts qualified sludge through solid fermentation and sterilization, and then uses the nitrogen, phosphorus, potassium and other components contained in the sludge to make organic fertilizer. In this process, biological agents can also be added to make bio-organic fertilizers. The equipment and process truly realize turning waste into treasure. Energy saving and environmental protection.